1

plan

Our collaboration is just the beginning. If you already have an idea for a custom glass bottle, we’ll work with you to address all the obvious issues, do our best to meet your needs, and put it into production. If you’re still undecided, we’ll develop a proposal tailored to your needs and goals. Throughout the process, we’ll communicate with you and make modifications until you’re satisfied.

2

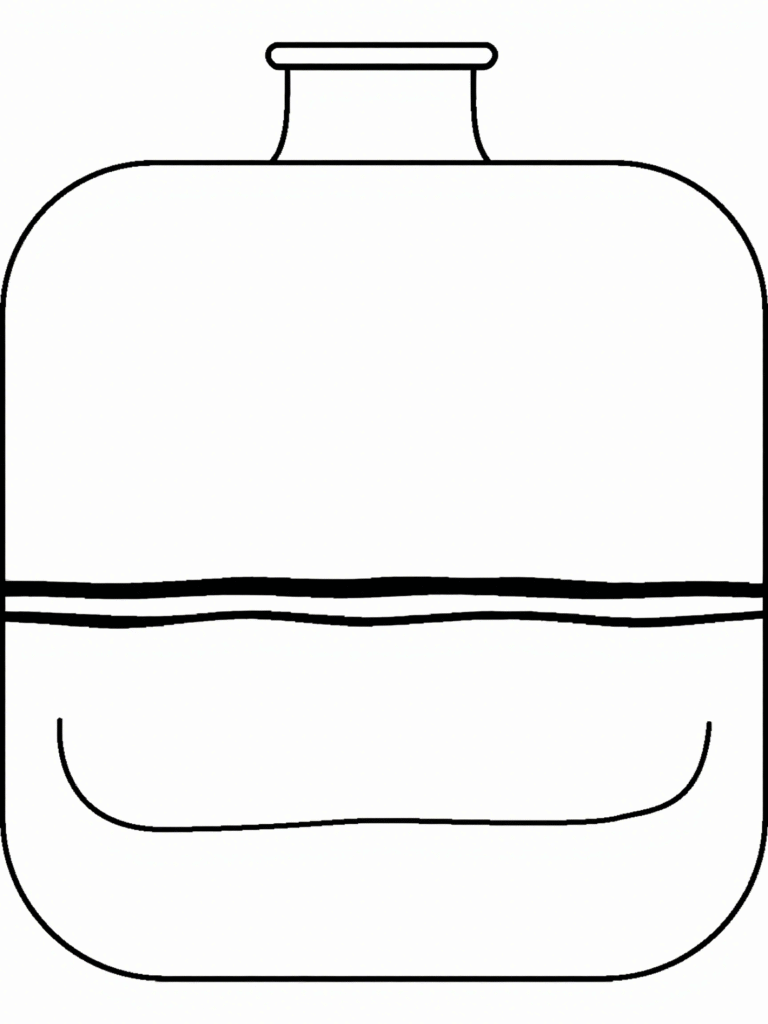

Technical drawings

The second step is to provide the bottle’s specific dimensions—height, capacity, aperture, base thickness, and neck finish. If you don’t have a clear reference or idea, you can tell us the intended use of the glass bottle and we’ll provide recommendations based on our experience. We’ll then create a technical drawing and send it to you for confirmation.

3

Rendering

Once the drawings are confirmed, we’ll finalize all the dimensions, digitize the new product, and render it to closely resemble the final product. You can see the final result firsthand. If you’re not satisfied, we’ll take the next step to optimize it.

4

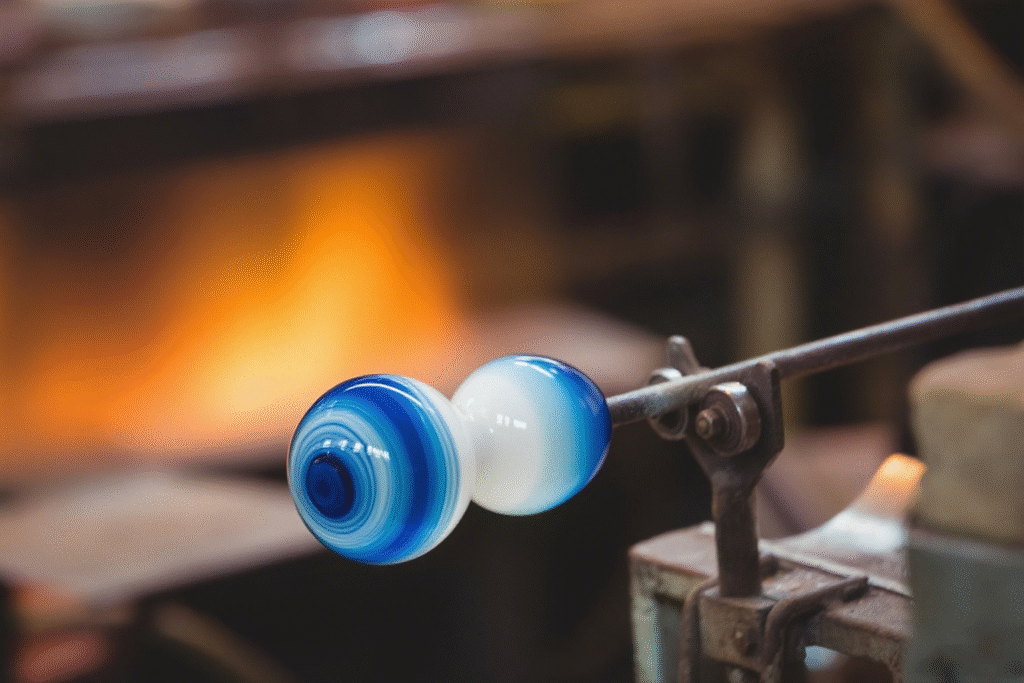

Test

In this step, we turn your design into reality. We’ll quickly contact the factory to produce sample bottles, including surface treatment, to meet your desired glass bottle specifications. This process takes some time, and we’ll discuss and confirm it with you. If you’re satisfied, we’ll quickly produce the bottles and confirm a delivery date based on your order. If there are any quality or design issues, we’ll contact the factory and design team to address them promptly.

5

Production

Finally, large-scale production. From raw materials to quality control, the whole process is transparent and we will track every step before shipment to ensure you can get high-quality bottles that you approve.